PCB Assembly Services

Hi-Tek Electronics delivers precision-driven PCB assembly services tailored to industries demanding the highest standards of quality. With expertise in surface-mount technology (SMT) and through-hole assembly, we excel in producing reliable and efficient assembled boards. Our advanced assembly process incorporates cutting-edge tools like pick-and-place machines, reflow ovens, x-ray, and AOI machines to ensure error-free results.

Serving automotive, aerospace, robotics, telecommunications, industrial, agriculture, intelligent transportation, security, medical sectors, and more, we’re committed to delivering excellence in printed circuit board assembly for applications requiring durability and precision.

Printed Circuit Board Assembly Services

NEW CUSTOMER?

No setup costs and no stencil charge on your first Assembly!

FLEXIBILITY

Full Kit, Partial Kit or Turnkey. We will work with you to provide exactly what you need!

SPEED

Speed - 5 or 10 Day Turn Time. Four available SMT lines to keep your order moving along and on time!

Why Choose Hi-Tek Electronics for PCB Assembly?

At Hi-Tek Electronics, we bring decades of experience and a proven track record of delivering superior PCB assembly services. Our state-of-the-art facilities feature the latest tools, including SMT, BGA, reflow ovens, x-ray, AOI machines, and wave soldering technology, enabling us to handle complex assembly processes with precision.

Our team’s commitment to clear communication and on-time delivery has earned us long-term partnerships with clients across industries. We understand the importance of accuracy, ensuring every assembled board meets exact specifications while staying within budget and timelines. With Hi-Tek, you gain a reliable partner focused on quality and customer satisfaction.

Types of PCB Assembly Services

Hi-Tek Electronics offers a comprehensive range of PCB assembly services to meet diverse project requirements. Whether your design calls for the precision of SMT assembly, the robust durability of through-hole assembly, or a hybrid solution, we have the expertise and equipment to deliver.

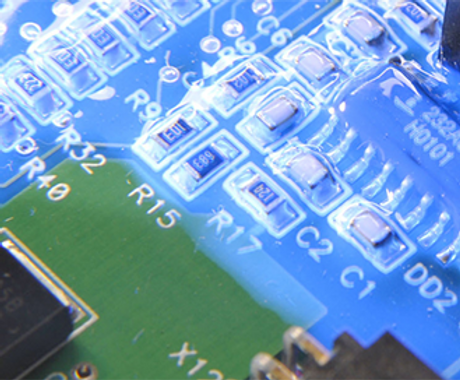

SURFACE MOUNT TECHNOLOGY ASSEMBLY (SMTA)

SMT assembly is a fast, efficient method where electronic components are mounted directly onto the PCB surface. Using pick-and-place machines and reflow ovens, this assembly process achieves high precision and is well-suited for compact designs and high-volume production. SMT assembly is cost-effective, reducing assembly times while ensuring reliability.

THROUGH HOLE PCB ASSEMBLY

Through-hole PCB assembly involves inserting hole components into drilled holes on the board and securing them with solder. This soldering method provides mechanical strength, making it ideal for high-stress applications in automotive and industrial systems. Hi-Tek’s wave soldering process ensures consistent results, while manual soldering allows for intricate details when needed.

MIXED TECHNOLOGY ASSEMBLY

For complex designs requiring both through-hole and surface-mount components, mixed technology assembly offers the best of both worlds. This approach integrates SMT assembly’s space efficiency with the durability of through-hole components, ensuring reliable functionality in hybrid designs.

Advanced Capabilities and Technology

Hi-Tek Electronics employs advanced technology to ensure the highest quality in every assembled board:

3D AOI Inspection

Our automatic optical inspection (AOI) machines provide precise defect detection for solder joints and component placement, ensuring error-free assemblies.

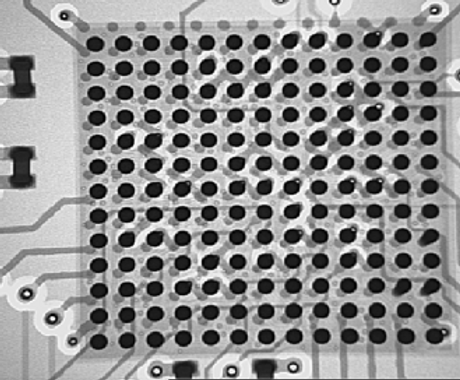

X-ray Inspection

Essential for complex PCBs, X-ray inspection uncovers hidden defects in solder joints and verifies internal structures with high accuracy.

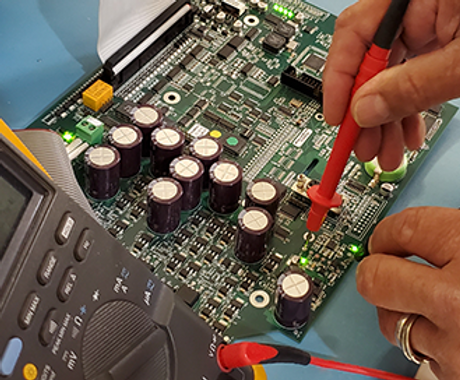

Testing

Comprehensive testing ensures that assembled boards meet all functional and performance requirements before delivery.

Conformal Coating

Protect your PCB assemblies from environmental factors with our conformal coating process, enhancing durability and reliability.

Programming

We offer programming services for ICs and other electronic components, using platforms like JTAG and Microchip to optimize functionality.

Quality Assurance and Compliance

Hi-Tek Electronics maintains rigorous quality assurance processes to deliver PCBs that exceed client expectations. We adhere to IPC Class II standards and operate in an ESD-protected environment to safeguard electronic components during assembly. From reviewing Gerber files and reference designators to implementing robust quality checks at every stage, our approach ensures consistency and reliability.

We accommodate both RoHS-compliant and leaded requirements, tailoring each project to meet specific needs. By combining advanced inspection techniques, including AOI and X-ray, with strict quality control, we guarantee error-free results in every board assembly.

Applications and Industries Served

Hi-Tek’s PCB assembly services cater to a wide range of industries, including automotive, aerospace, robotics, telecommunications, industrial, agriculture, intelligent transportation, security, medical sectors, and more. Our expertise supports critical applications, from advanced communication systems to medical diagnostic devices.

With the flexibility to handle custom designs and complex assemblies, Hi-Tek Electronics delivers tailored solutions to meet the unique demands of each industry. Whether producing compact, high-precision boards or robust, high-durability assemblies, we ensure your products perform flawlessly.

Facility and Equipment

Hi-Tek’s more than 25,000-square-foot facility is equipped with cutting-edge tools designed for modern PCB assembly challenges. Our pick-and-place machines ensure accurate component placement, while reflow ovens and wave soldering processes guarantee robust connections.

AOI machines and X-ray inspection systems provide unparalleled quality control, and our use of stainless steel fixtures enhances the durability of our processes. We continuously invest in advanced technology to handle shrinking component sizes and increasing design complexities, ensuring we’re prepared for the future of electronic manufacturing.

FAQS

What PCB assembly services does Hi-Tek Electronics offer? We provide SMT assembly, through-hole assembly, mixed technology assembly, programming, testing, and conformal coating services.

How does Hi-Tek ensure quality during the assembly process? We use advanced tools like AOI machines, X-ray inspection, and reflow ovens, along with rigorous quality checks, to ensure error-free boards. We will be ISO 9001:2015, ISO 13485, and AS9100-D certified in the summer of 2025.

Can Hi-Tek handle custom designs and requirements? Yes, we tailor our services to meet the specific needs of each client, including reviewing Gerber files and working with unique designs.

What is the advantage of mixed technology assembly? Mixed technology assembly combines the durability of through-hole components with the space efficiency of SMT components, offering a versatile solution for complex designs.

What equipment does Hi-Tek use for PCB assembly? Our facility includes pick-and-place machines, reflow ovens, AOI machines, wave soldering equipment, and X-ray inspection systems for precise and reliable assemblies.

What industries do you serve? We serve industries like automotive, aerospace, robotics, telecommunications, industrial, agriculture, intelligent transportation, security, medical sectors, and more, delivering high-quality PCB assemblies for various applications.

At Hi-Tek Electronics, customer satisfaction drives everything we do. Many of our clients have been with us for over a decade, reflecting the trust we’ve built through consistent delivery and quality. By maintaining flexibility and adapting to evolving requirements, we consistently exceed expectations.

Partner with Hi-Tek Electronics for dependable, high-quality PCB assembly services. Our expertise, state-of-the-art equipment, and commitment to excellence ensure your project’s success. Contact us today to discuss your requirements and experience the difference of working with a trusted industry leader.

CONTACT US

3915 Fairview Industrial Dr., Suite 150

Salem, OR 97302

503-364-9257 Toll Fee: 1-800-364-9257